SPACCER is the lift with additional improvement of the driving dynamics in the limit area

The patented SPACCER system for cars, mobile homes and commercial vehicles increases driving comfort and improves the road holding of the vehicle.

At the same time, the roll point is reduced. From a physical point of view, it influences the cornering behavior of the vehicle via the vehicle springs. This is neutralized and improved by the vehicle lift with the SPACCER. 95% of the car manufacturers install longer shock absorbers to enable the car to be raised later (unfortunately, most people are not aware of this).

Perfectly developed custom-made lift kit according to the chassis number

Due to the too long original shock absorber piston rods, the vehicles in the standard condition often appear a bit spongy and in the limit area the car often tends to oversteer. SPACCER® improves the driving behavior because the car can no longer swing up so far. The driving behavior is noticeably better with the same spring characteristics / spring comfort. So the question arises: "Why do automobile manufacturers install shock absorber piston rods that are too long?" The reason is quite simple. Automobile manufacturers sell vehicles worldwide. And it is therefore plausible that a normal car cannot drive with standard spring deflections on the roads in Afghanistan, for example. Just as little as a hunter who constantly has to drive on bad roads would have too little spring travel. There are many examples and so you can logically put the car higher, otherwise many car manufacturers would not be able to sell their vehicles. The technology is already installed and what is possible can be measured via the remaining spring travel: www.spaccer.com

Specially made springs for lifting was yesterday

Manufacturers of accessory springs for retrofitting must always change the characteristics of the original springs in order not to infringe the copyright of the automobile manufacturer. It is almost impossible for a manufacturer of accessory springs to go into detail about every characteristic curve of a spring. As a rule, a spring is then manufactured for different types, although a petrol model (light spring) and a diesel model (heavy spring) are different.

Here is an example: A single vehicle type has up to 30 different springs on the front and rear axles. The aftermarket would therefore have to produce 30 different suspension springs.

This is economically impossible and a reason why a spring is produced for a vehicle type, which often acts too hard and is uncomfortable to drive in practice. In addition, the height cannot be adjusted.

7 different springs for a vehicle

A typical example of the many different springs on a vehicle type. In this example the Opel Grandland X. This has seven different springs - for one year of manufacture.

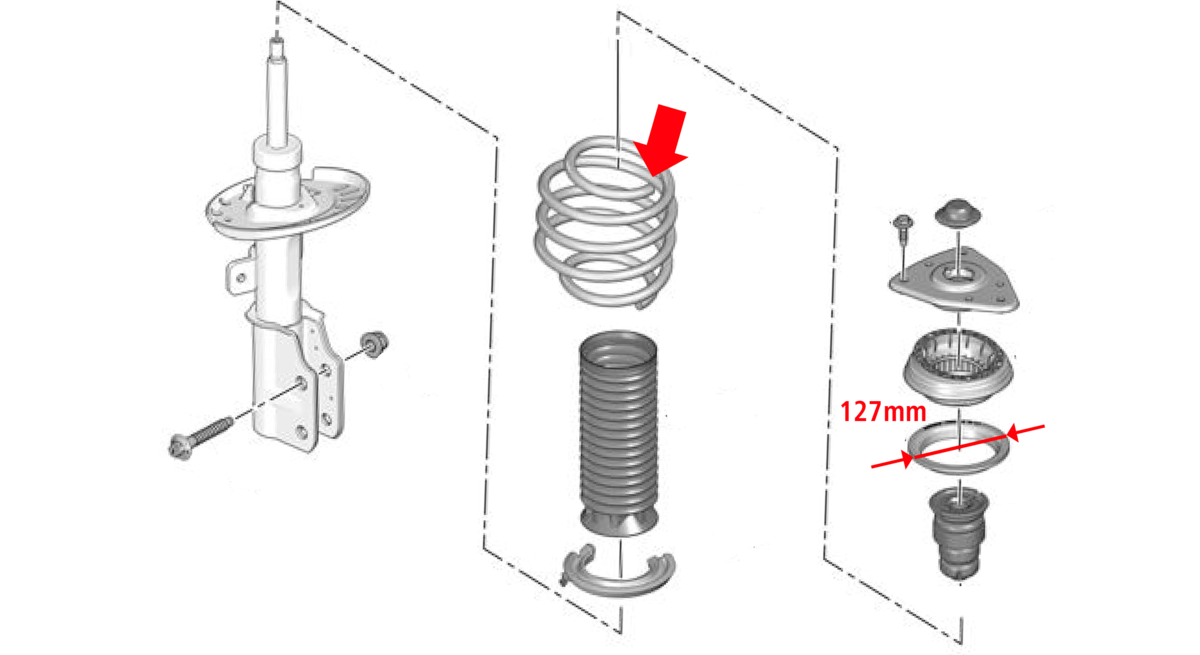

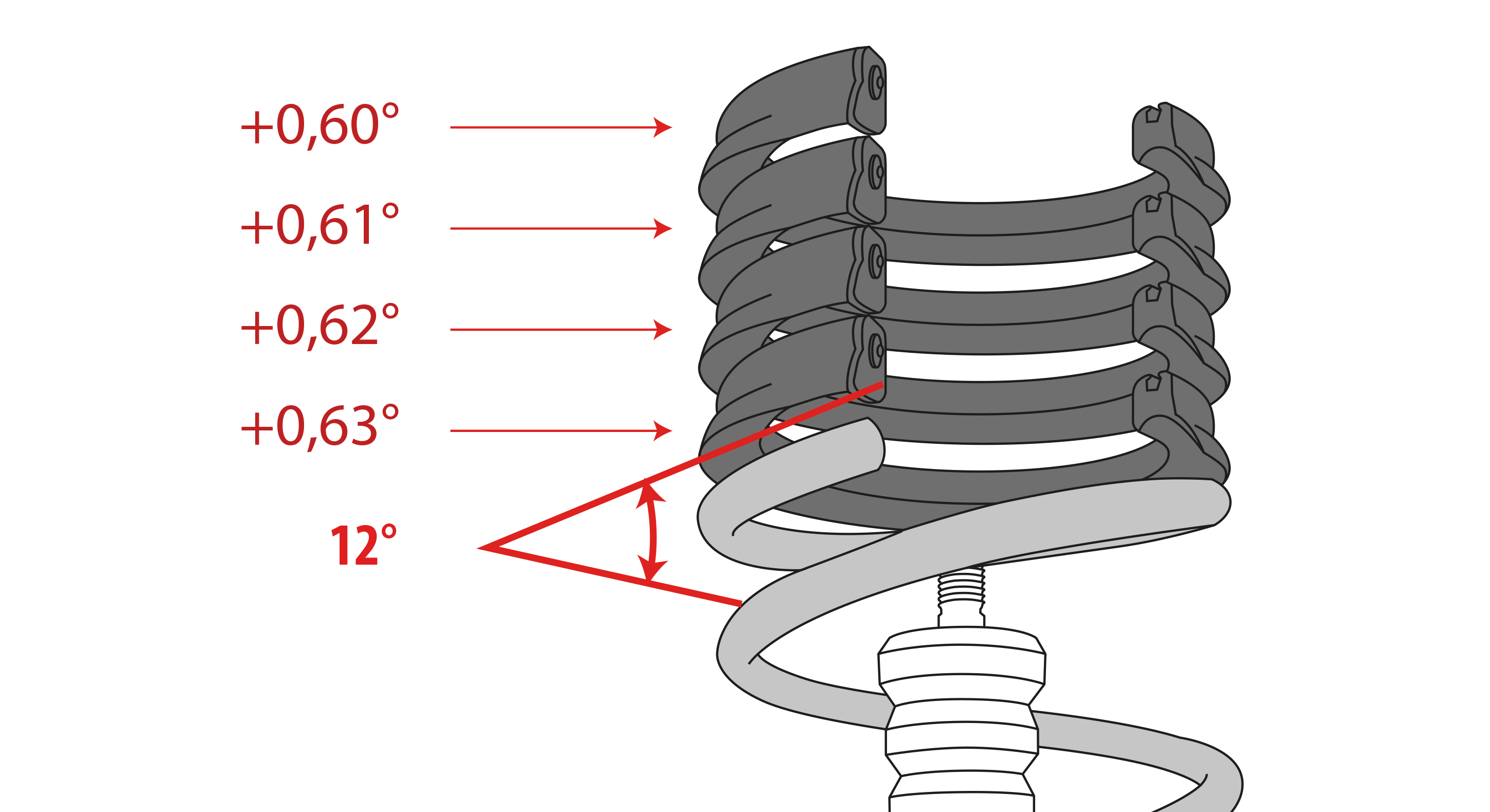

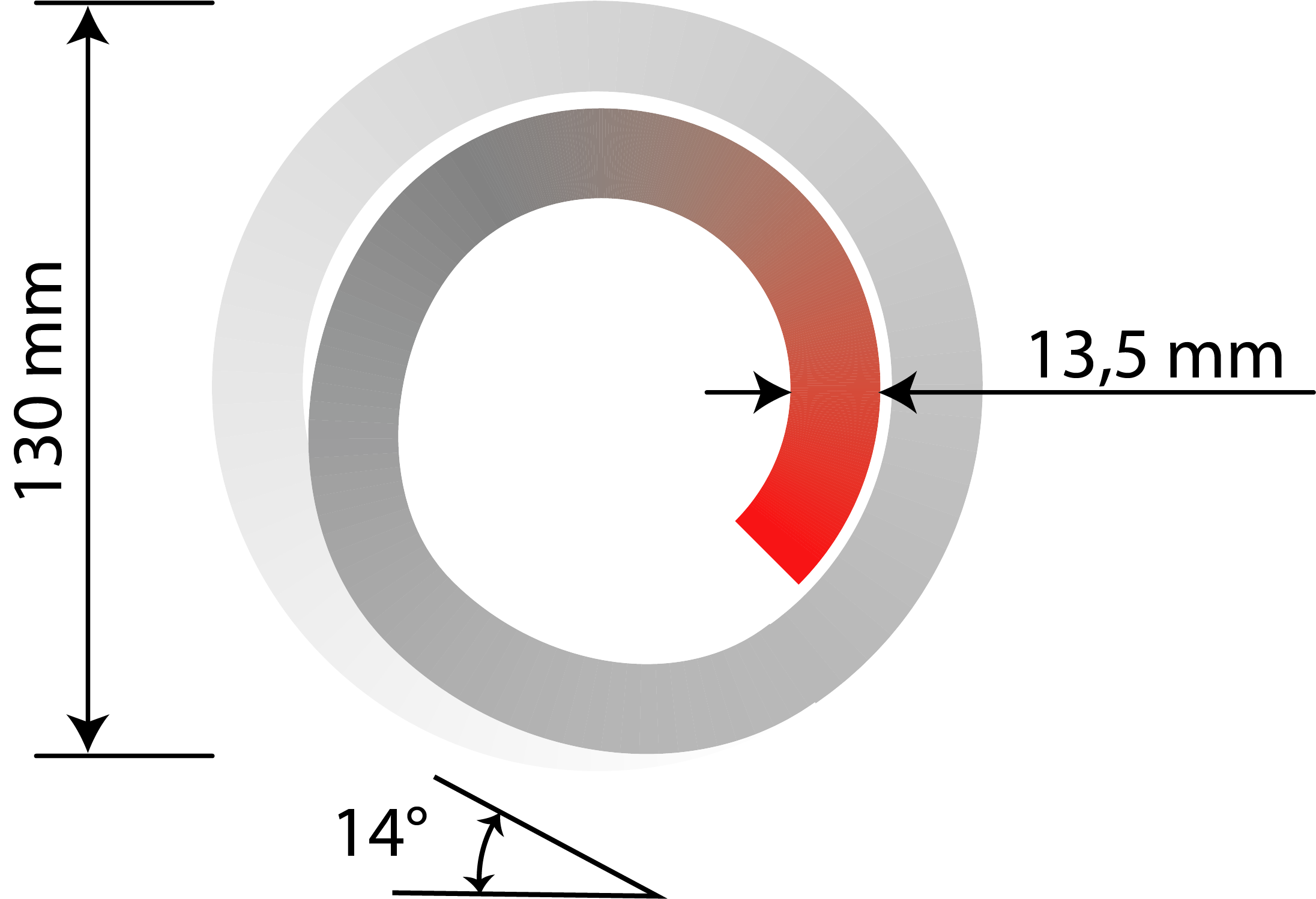

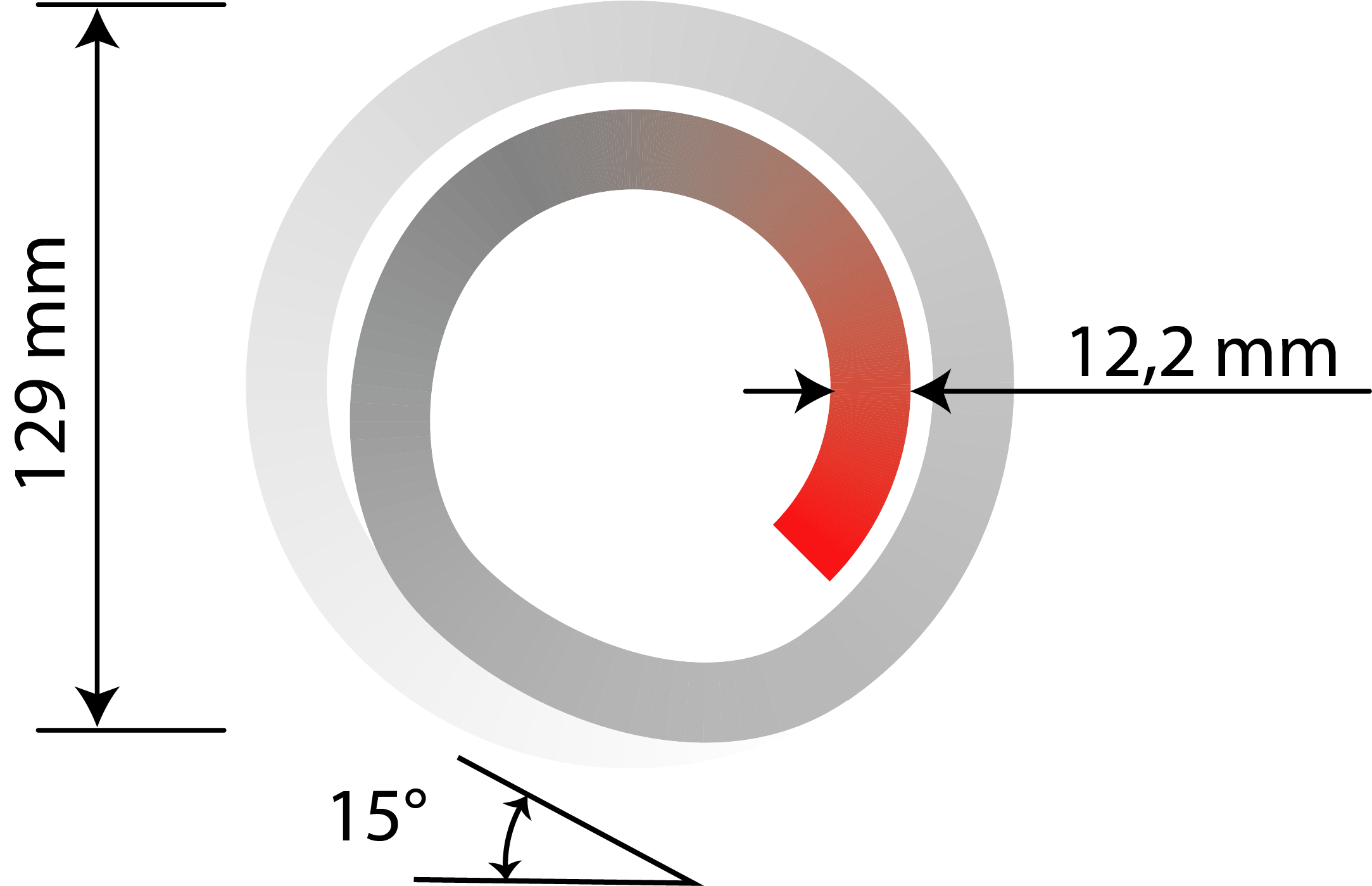

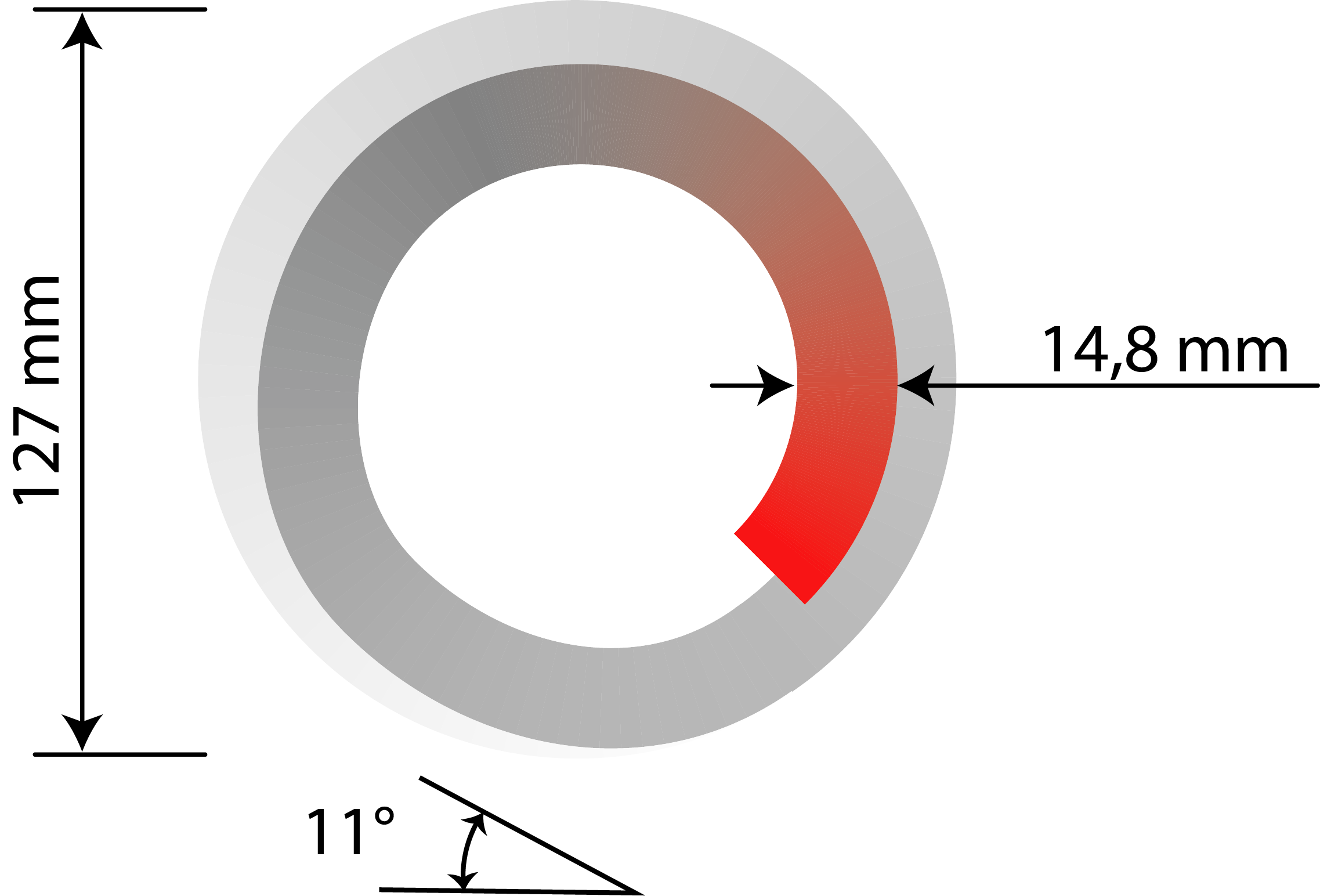

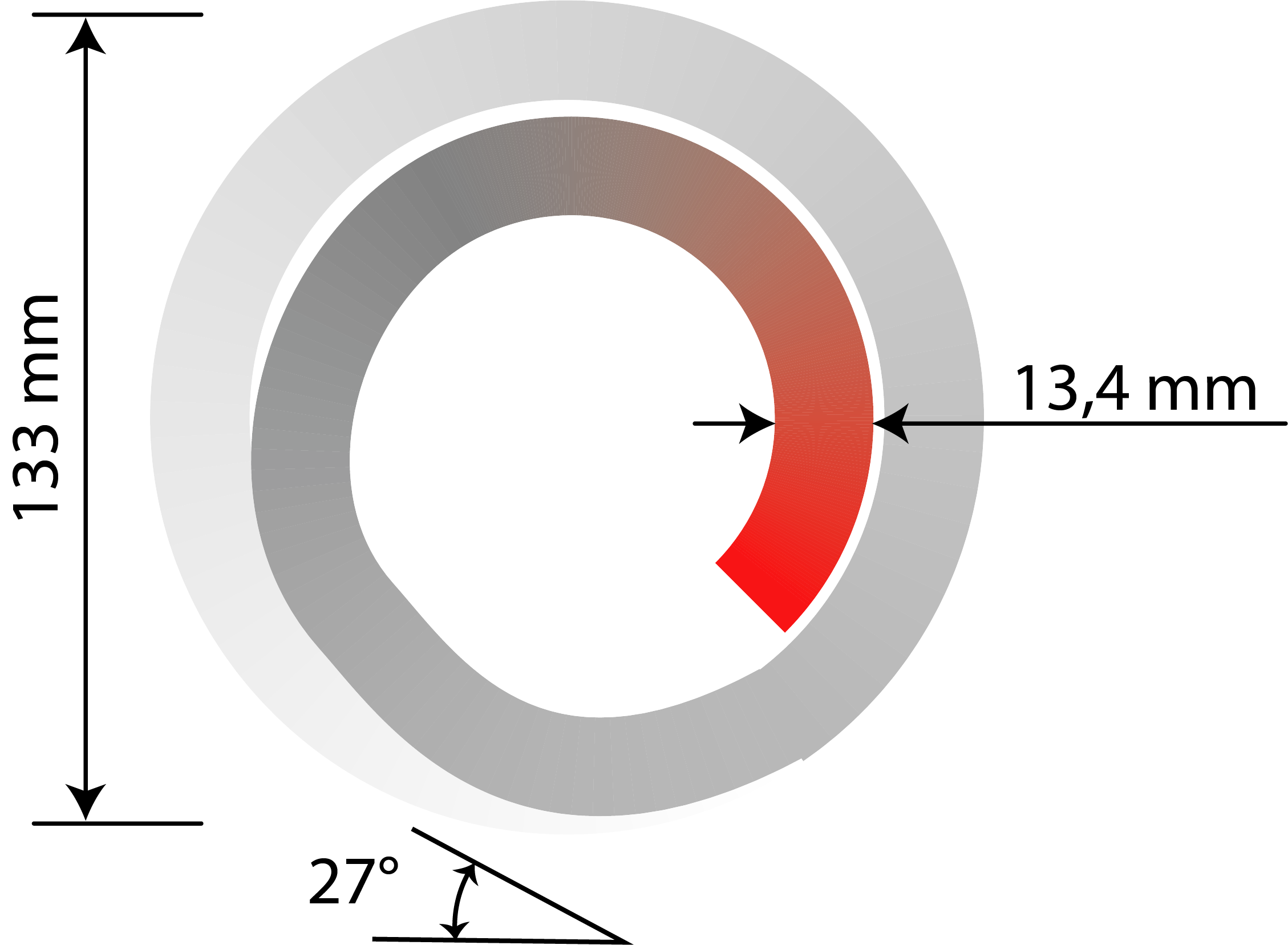

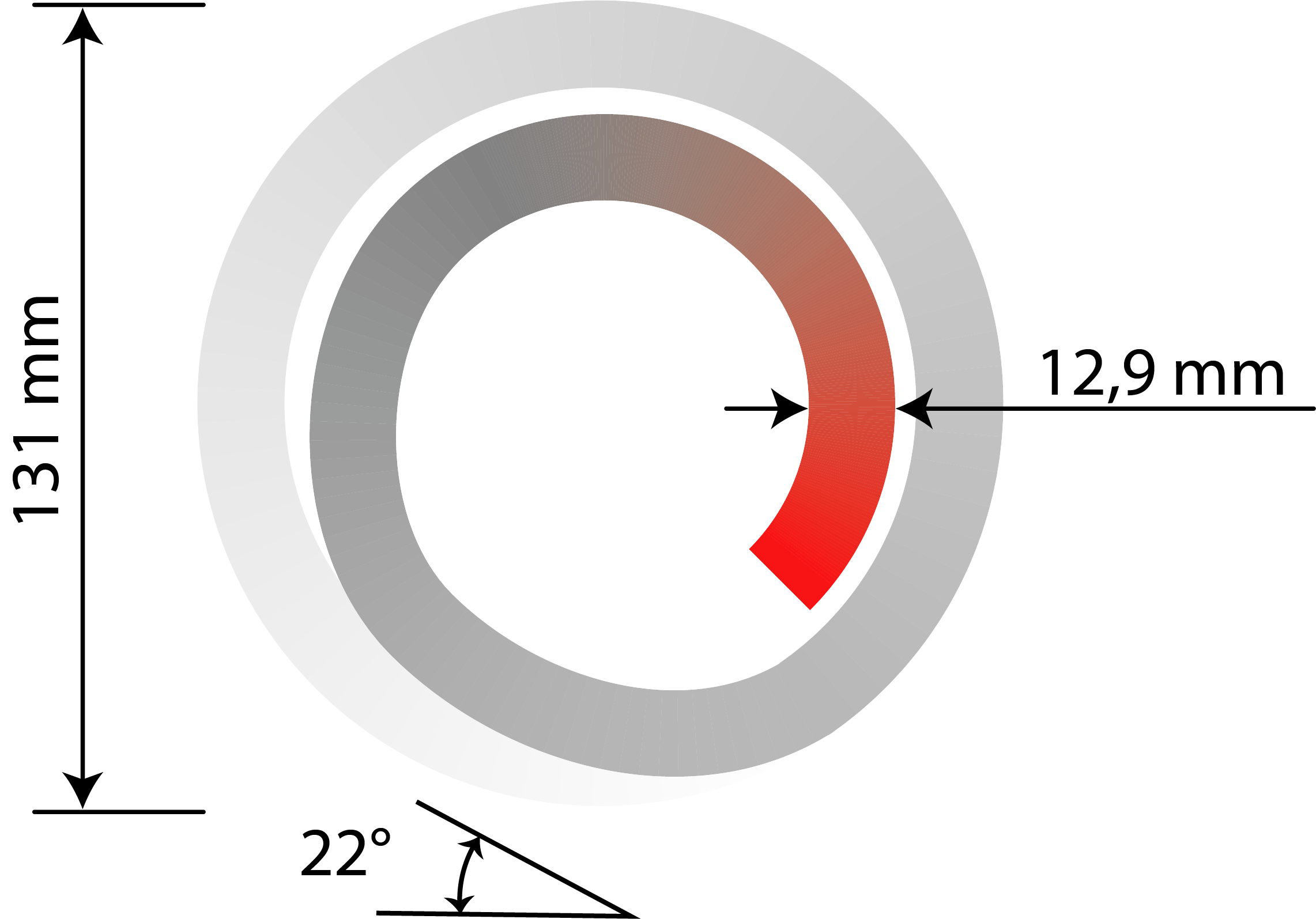

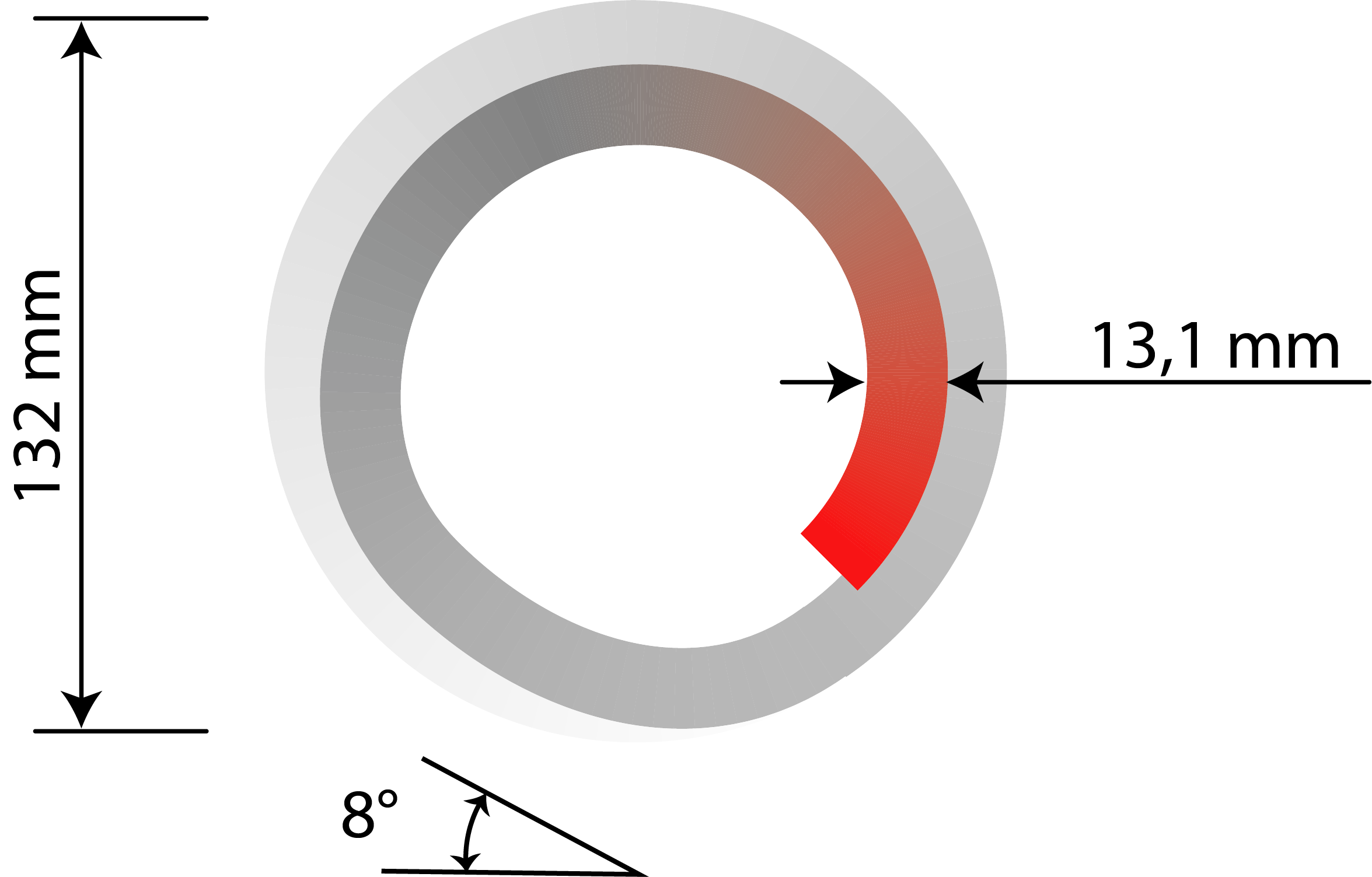

SPACCER® manufactures exactly according to the chassis number so that they fit the different springs 100%. The cathedral bearing always remains the same. The SPACCER® are manufactured using the 3D process. It is therefore important that the spring outlets are tailored to the following parameters:

- Angle degrees

- Diameter

- Spring wire thickness

- Bending angle of the spring (see pictures below)

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 690 80 | MEDIUM MEDIUM AND DIESEL DW10FD FAP 110 KW AND NORMAL SUSPENSION AND ML6C OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND DIESEL DW10FD FAP 110 KW AND REINFORCED SUSPENSION FRONT AND REAR AND ML6C OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND DIESEL DW10FD FAP 110 KW AND SUSPENSION FR REINFORCED AND HI RAISED AND ML6C OR CROSS OVER 5 DOORS AND BOTTOM BOTTOM + AND DIESEL DW10FD FAP 110 KW AND SUSPENSION FR REINFORCED AND HI RAISED AND ML6C | 1 VIOLET + 1 YELLOW + 1 YELLOW |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 690 80 | CROSS OVER 5 DOORS AND LOW MEDIUM AND DIESEL DW10FC FAP 132 KW AND REINFORCED SUSPENSION FRONT AND RIGHT AND GEAR TYPE AMN8 OR CROSS OVER 5 DOORS AND LOWER BOTTOM + AND DIESEL DW10FC FAP 132 KW AND REINFORCED SUSPENSION FRONT AND RIGHT AND GEAR TYPE AMN8 OR MEDIUM MEDIUM AND DIESEL DW10FC FAP 132 KW AND NORMAL SUSPENSION AND TRANSMISSION TYPE AMN8 OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND DIESEL DW10FC FAP 132 KW AND REINFORCED SUSPENSION FRONT AND REAR AND TRANSMISSION TYPE AMN8 | 1 VIOLET + 1 YELLOW + 1 BLUE |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 690 80 | CROSS OVER 5 DOORS AND LOWER BOTTOM + AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FRONT AND HI AND ML6C OR CROSS OVER 5 DOORS AND LOWER BOTTOM + AND DV5RC 96 KW 1.5L DIESEL AND LOWERED SUSPENSION AND ML6C OR LOWER MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND REGULAR SUSPENSION AND ML6C OR CROSS OVER 5 DOORS AND LOW MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FR AND HI AND ML6C OR LOW MEDIUM AND TURBO DIESEL DV6FC FAP 88 KW AND NORMAL SUSPENSION AND ML6 C OR LOW MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND LOWERED SUSPENSION AND ML6C OR LOW MEDIUM AND TURBO DIESEL DV6FC FAP 88 KW AND LOWERED SUSPENSION AND ML6C | 1 ORANGE + 1 YELLOW + 1 GELB |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 691 80 | CROSS OVER 5 DOORS AND LOWER BOTTOM + AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FRONT AND HI AND TRANSMISSION TYPE ATN8 OR CROSS OVER 5 DOORS AND MIDDLE MIDDLE AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FRONT AND HI AND ML6C OR CROSS OVER 5 DOORS AND LOWER BOTTOM + AND INJECTION EP6FDT M 120 KW PETROL AND SUSPENSION VO REINFORCED AND HI RAISED AND AUTOMATIC TRANSMISSION AT6 3 OR CROSS OVER 5 DOORS AND LOWER MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FR AND HI AND GET RUBE TYPE ATN8 OR MEDIUM MEDIUM AND INJECTION EP6FDT M 120 KW PETROL AND REINFORCED SUSPENSION FR AND HI AND AUTOMATIC TRANSMISSION AT6 3 OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND INJECTION EP6FDT M 120 KW PETROL AND SUSPENSION FR REINFORCED AND HI RAISED AND AUTOMATIC GRATE AT6 3 OR LOW MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND NORMAL SUSPENSION AND TRANSMISSION TYPE ATN8 OR MEDIUM MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND NORMAL SUSPENSION AND ML6C OR MEDIUM MEDIUM AND TURBO DIESEL DV6FC FAP 88 KW AND NORMAL SUSPENSION AND ML6C OR MEDIUM MEDIUM AND DV5RC 96 Week 1.5 L DIESEL AND LOWERED SUSPENSION AND ML6C OR LOW MEDIUM AND TURBODIESEL DV6FC FAP 88 KW AND NORMAL SUSPENSION AND AUTOMATIC TRANSMISSION AT6 3 OR MEDIUM MEDIUM AND TURBODIESEL DV6FC FAP 88 KW AND LOWERED SUSPENSION AND ML6C OR MEDIUM MEDIUM AND TURBODIESEL DV6FC FAP 88 KW AND WITHOUT AMPLIFICATION RECTIFIER AND AUTOMATIC TRANSMISSION AT6 3 OR MEDIUM MEDIUM AND TURBO DIESEL DV6FC FAP 88 KW AND WITHOUT GLASS ROOF AND NORMAL SUSPENSION AND EQUALIZER AMPLIFIER WITH PREMIUM 12 CHANNELS AND AUTOMATIC TRANSMISSION AT6 3 | 1 ORANGE + 1 YELLOW + 1 BLUE |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 693 80 | MEDIUM MEDIUM AND TURBO DIESEL DV6FC FAP 88 KW AND ELECTRICAL ACTUATION DRIVER'S SEAT + ADJUSTMENT OF SEAT CUSHION FRONT PART AND EQUALIZER AMPLIFIER WITH PREMIUM 12 CHANNELS AND AUTOMATIC TRANSMISSION AT6 3 EXCEPT WITHOUT GLASS ROOF OR MEDIUM MEDIUM AND DV5RC 96 KW 1.5L DIESEL AND NORMAL SUSPENSION AND TRANSMISSION TYPE ATN8 OR CROSS OVER 5 DOORS AND CENTER MIDDLE AND DV5RC 96 KW 1.5L DIESEL AND REINFORCED SUSPENSION FRONT AND REAR AND TRANSMISSION TYPE ATN8 | 1 ORANGE + 1 YELLOW + 1 GREEN |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 695 80 | Cross Over 5 doors and below + and EB2ADTS 96 KW 1200 3 cylum petrol and normal uprising and manual transmission MC or Cross Over 5 doors and below + and EB2ADTS 96 kW 1200 3 cylum petrol and lowered suspension and switching transmission MC or Cross OVER 5 DOORS AND LOWER MIDDLE AND EB2ADTS 96 KW 1200 3 CYL PETROL AND NORMAL SUSPENSION AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND LOWER LOWER + AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND HI AND MANUAL TRANSMISSION MC OR CROSS OVER5 DOORS AND LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND LOWERED SUSPENSION AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND LOWER LOWER + AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSIONS SUSPENSION FRONT AND HIGH AND MANUAL TRANSMISSION MB6 OR CROSS OVER 5 DOORS AND LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND HIGH AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND MIDDLE MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND HIGH AND MANUAL TRANSMISSION MB6 OR CROSS OVER 5 DOORS AND LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND HIGH AND MANUAL TRANSMISSION MB6 OR LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND NORMAL SUSPENSION UNG AND MANUAL TRANSMISSION MB6 OR LOW MEDIUM AND INJECTION EB2DTS 96 KW AND LOWERED SUSPENSION AND MANUAL TRANSMISSION MC OR LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND LOWERED SUSPENSION AND MANUAL TRANSMISSION MB6 OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND NORMAL ON SUSPENSION AND MANUAL TRANSMISSION MB6 OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND LOWERED SUSPENSION AND WITHOUT GAIN RECTIFIER AND MANUAL TRANSMISSION MB6 OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND WITHOUT GLASS ROOF AND LOWERED SUSPENSION AND EQUALIZER AMPLIFIER WITH PREMIUM 12 CHANNELS AND MANUAL TRANSMISSION MB6 OR LOW MEDIUM AND INJECTION EB2DTS 96 KW AND REGULAR SUSPENSION AND MANUAL TRANSMISSION MC | 1 RED + 1 YELLOW + 1 YELLOW |

| SPRING SPOUT | PART NUMBER | SUITABLE FOR | COLOR CODING |

|---|---|---|---|

| 98 154 697 80 | MEDIUM MEDIUM AND INJECTION EB2DTS 96 KW AND NORMAL SUSPENSION AND AUTOMATIC TRANSMISSION AT6 3 OR LOW MEDIUM AND INJECTION EB2DTS 96 KW AND NORMAL SUSPENSION AND AUTOMATIC TRANSMISSION AT6 3 OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND EB2ADTS 96 KW 1 200 3 CYL PETROL AND LOWERED SUSPENSION AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND CENTER MIDDLE AND EB2ADTS 96 KW 1200 3 CYL PETROL AND NORMAL SUSPENSION AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND LOWER LOWER + AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FROM AND HI AND TRANSMISSION TYPE ATN8 OR CROSS OVER 5 DOORS AND CENTER MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND REAR AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND CENTER MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION VO AND HI AND TRANSMISSION TYPE ATN8 EXCEPT SEAT CONTROL DRIVER WITH MEMORY EXCEPT ELECTRIC CONTROL DRIVER'S SEAT + ADJUSTMENT SEAT CUSHION FRONT PART OR CROSS OVER 5 DOORS AND LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND REINFORCED SUSPENSION FRONT AND HOW AND TRANSMISSION TYPE ATN8 OR MEDIUM MEDIUM AND INJECTION EB2DTS 96 KW AND LOWERED SUSPENSION AND MANUAL TRANSMISSION MC OR CROSS OVER 5 DOORS AND MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND WITHOUT GLASS ROOF AND REINFORCED SUSPENSION FRONT AND REAR AND TRANSMISSION TYPE ATN8 OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND WITHOUT GLASS ROOF AND NORMAL SUSPENSION AND WITHOUT GAIN RECTIFIER AND GEAR TYPE ATN8 OR LOW MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND NORMAL SUSPENSION AND GEAR TYPE ATN8 OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND SEAT ACTUATOR DRIVER WITH STORAGE AND LOWERED SUSPENSION AND EQUALIZER AMP WITH PREMIUM 12 CHANNELS AND MANUAL TRANSMISSION MB6 EXCEPT WITHOUT GLASS ROOF OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND WITHOUT GLASS ROOF AND NORMAL SUSPENSION AND EQUALIZER AMPLIFIER WITH PREMIUM 12 CHANNELS AND TRANSMISSION TYPE ATN8 OR MEDIUM MEDIUM AND INJECTION EB2DTS 96 KW AND NORMAL SUSPENSION AND SWITCHG ETRIEBE MC OR MEDIUM MEDIUM AND EB2ADTS 96 KW 1200 3 CYL PETROL AND ELECTRICAL ACTUATION DRIVER'S SEAT + ADJUSTMENT OF FRONT SEAT CUSHION AND LOWERED SUSPENSION AND EQUALIZER AMPLIFIER WITH PREMIUM 12 CHANNELS AND MANUAL TRANSMISSION MB6 EXCEPT WITHOUT GLASS ROOF | 1 RED + 1 YELLOW + 1 BLUE |

The perfect solution

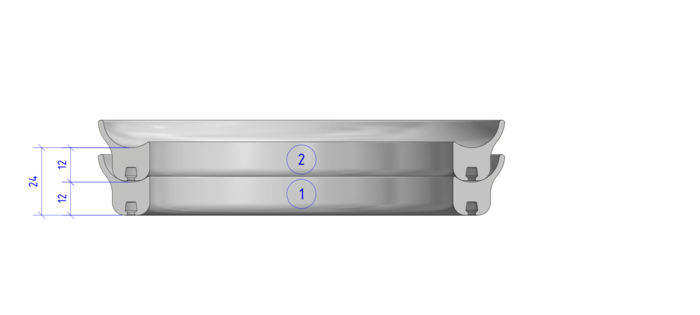

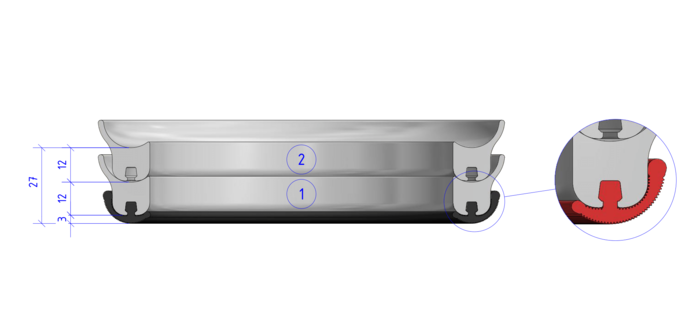

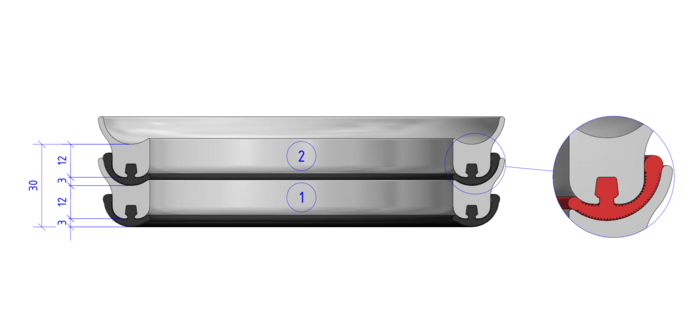

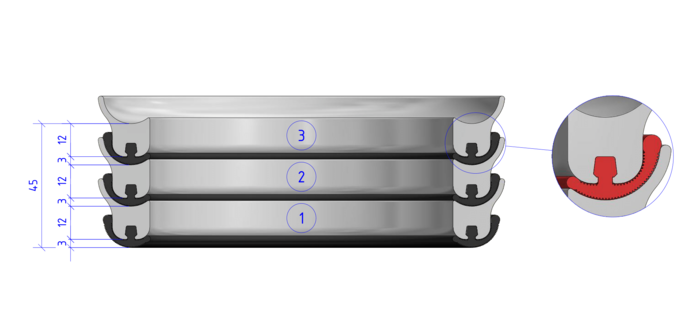

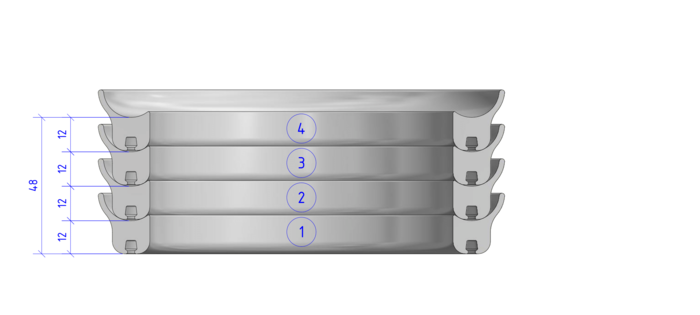

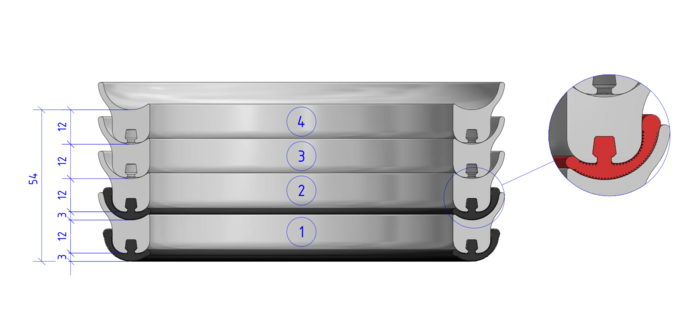

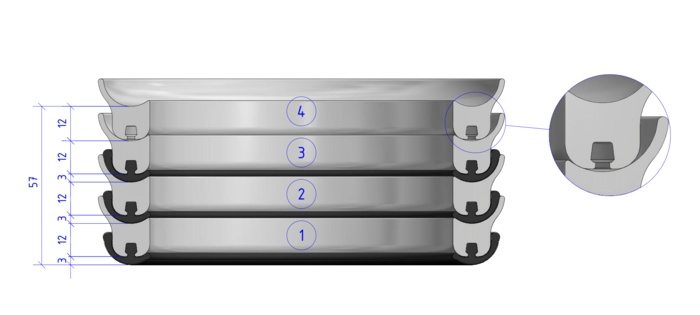

With SPACCER, on the other hand, the situation is completely different because the system is exclusively geared towards raising the springs. SPACCER offers a multi-stage lift of 12mm, 24mm, 36mm and 48mm with or without a rubber profile for the perfect adjustment of the height (1 SPACCER = 12mm lift + 3mm per SPACCER for a rubber profile). No spring manufacturer can offer that. With the SPACCER system, the customer gets exactly what he wants without any disadvantages for the driving dynamics.

In summary, this means: The car manufacturers generally install longer shock absorber piston rods for their vehicles that can be used worldwide, so the car manufacturer has already prepared the lift kit. The entire axle geometry of the vehicle is already geared towards lifting. With leaflet 751 Appendix 2, the KBA (German Federal Motor Transport Authority) makes clear specifications for lifting. The approvals issued by the TÜV for the residual spring travel can be read on the SPACCER homepage at www.spaccer.com.

lifting platform

Residual spring travel has been checked by the automobile manufacturer

- Steering, tipping and braking behavior with handling in unloaded and loaded condition - keyword: permissible axle loads

- Driving behavior at high speeds

- Driving behavior on bad roads

- strength of the components

- Load on the chassis springs and attachments

- Angle difference of cardan / cardan shafts

Block dimensions and block dimension reserves of the suspension springs are supplied free of charge by SPACCER spring travel limiters. The piston strokes of the shock absorbers remain technically unchanged.

Electronic dampers are not affected by the lift kit. This is the flow of oil in the damper.

At SPACCER, everything is perfectly matched to each individual vehicle using the chassis number. SPACCER are produced using data from the original spring in a 3D process. There are no known technical disadvantages when adhering to the remaining spring travel.

At www.spaccer.com you can read what is technically permissible for the vehicle in question, without any disadvantages for driving dynamics.

SPACCER International is a protected world brand and delivers to more than 150 countries on all continents. SPACCER International manufactures for over 300 automobile manufacturers, over 7,000 vehicle models and almost 60,000 types of springs. SPACCER are made for 98% of all vehicles in Germany. Inventor and patent owner is Franz Hamann with 40 years of experience in the fields of tuning, chassis technology and racing. SPACCER was founded in 2000. After 8 years of research and development, sales officially started in 2008.

In addition to private customers and dealers, we also supply large corporations such as Europe's largest car dealership, Porsche Holding in Salzburg. It is a 100www.spaccerisrael.co.ilubsidiary of Volkswagen AG with 32,900 employees, active in 22 European countries as well as in Colombia, Chile, China, Malaysia, Singapore, Brunei and Japan, where SPACCER is listed as a factory supplier. As a globally recognized and protected brand, SPACCER is recognized in the countries as a solution partner - from conception to execution to support and aftersales. SPACCER meets the requirements for technical vehicle acceptance worldwide - in Switzerland, for example, with a FAKT test report and a declaration of suitability for the SPACCER. Depending on the remaining spring deflection, a lift of up to 48 cm is possible with acceptance by the motor vehicle inspection (MFK). All other countries and regions are managed centrally by SPACCER International. The Middle East/Africa region is controlled by SPACCER Israel where all government requirements and tests have been met. According to customs guidelines, entries can be made directly in the vehicle registration document. SPACCER® is the first recognized and accepted manufacturer for vehicle lifts in Israel. For more information, see www.spaccerisrael.co.il. SPACCER is a registered trademark Made in Germany!